Car manufacturers will say that their models use xxxx MPa ultra-high-strength steel plate, want to know which parts of the body need high-strength or ultra-high-strength materials, why?

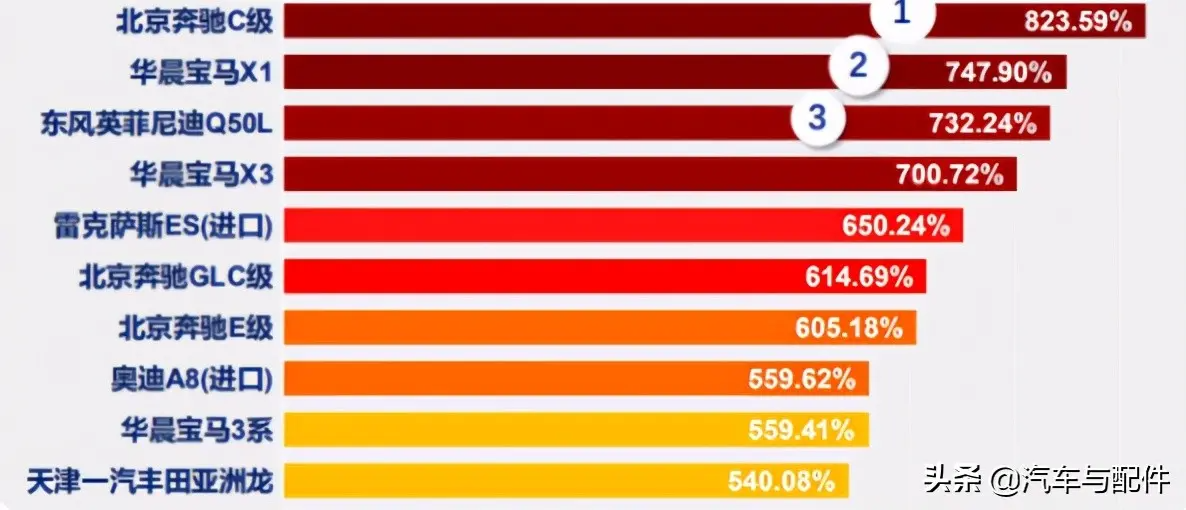

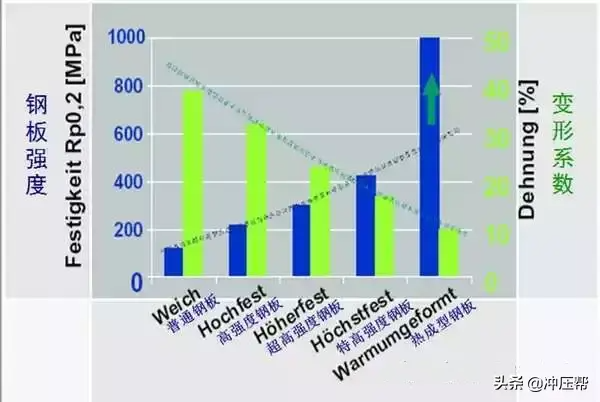

The automotive industry's classification of steel plate strength is as follows (data from a year ago, please correct if there is a discrepancy)

The yield strength of more than 300Mpa can be called ultra-high-strength steel plate, more than 1000Mpa is generally hot-stamped steel plate, ordinary steel is difficult to achieve this strength. The hot-formed steel plate undergoes high-temperature forming and a series of heat treatments during processing, with ultra-high strength and a very small deformation coefficient.

The yield strength of more than 300Mpa can be called ultra-high-strength steel plate, more than 1000Mpa is generally hot-stamped steel plate, ordinary steel is difficult to achieve this strength. The hot-formed steel plate undergoes high-temperature forming and a series of heat treatments during processing, with ultra-high strength and a very small deformation coefficient.

At present, major manufacturers are popularizing the use of hot-stamping steel, which has high strength and light weight, and is still high in fuel saving and emission reduction. Good steel should be used on the blade, and ultra-high-strength steel is used in places that save the lives of passengers in the event of an accident.

无论是遇到正碰侧碰还是翻滚,最大程度保持乘客所在的座舱完整是最重要的,因此车身的下部,侧围内板(ABC柱)和顶盖横梁就成为了使用超高强度钢材最密集的车身部位。

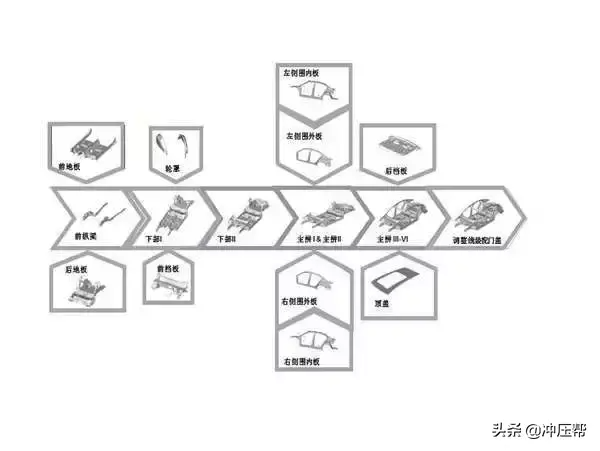

下面这张图大概说明了车身的制造流程,可以看看上面说的下部/侧围都是什么。

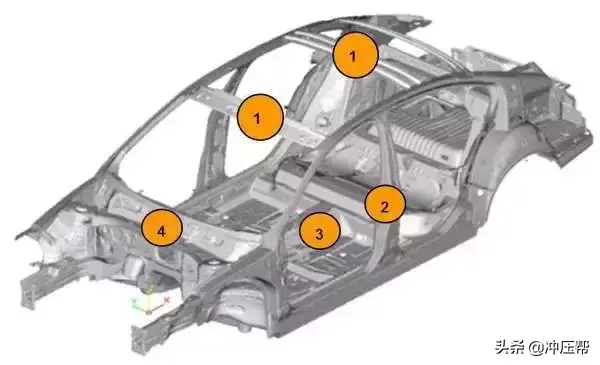

Let's disassemble the body parts using ultra-high-strength steel plates one by one

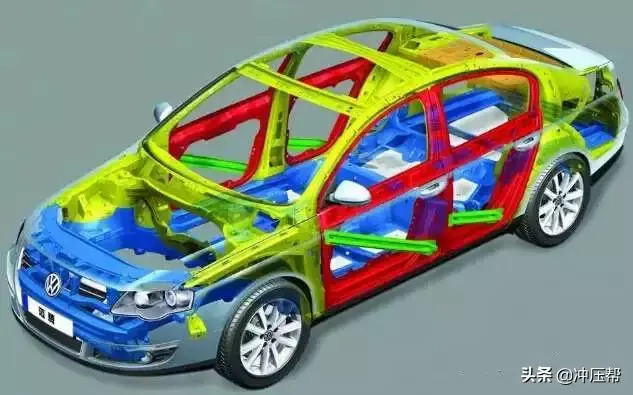

This figure illustrates where ultra-high strength (hot-stamped steel plates) are mainly used in the body-in-white frame, and the door crash beams and front and rear impact beams are not shown. This drawing does not include four doors / two covers / fenders / side peripheral outer panels / top cover and other exterior surface parts, the general consumer said that the thickness of the steel plate is the thickness of these outer surface parts, in fact, the body safety and the thickness of the steel plate of the outer surface parts have nothing to do with it, only related to the structure of the body and the key parts of the plate / connection strength.

- Top cover beam

- Body side inner panels (including ABC pillars)

- Lower middle aisle (Autohome Xiaobian takes the amount of Iphone5 every day that affects the comfort of rear passengers)

- Front bezel

Let's talk about them one by one

- The top cover beam can ensure the integrity of the passenger compartment without deformation to the greatest extent when the body rolls, there is nothing to say, it should be used.

- The side circumference of the body is also a very important safety-related component, and a large number of high-tech body parts such as ultra-high-strength steel plates and laser welding are used, and laser welding of the door frame and roof lap area can greatly improve safety. The lower part of the body, where the light of day is never seen, the place where ordinary consumers will never pay attention, is also the focus area of intensity.

The places marked yellow are all parts that use ultra-high-strength steel plates, and the finer disassembly diagram is not on, so let's make do with it.

The main part is like this, there are many small parts also use ultra-high-strength steel plates, not one by one, the disassembly is too detailed if it involves corporate confidentiality regulations, for their own safety will not be disassembled, everyone look at a few approximate schematic diagrams. Any form of opinion is welcome to be expressed and discussed!