Today we will talk about a more important position, that is, the beam head in the body skeleton. The concept of Liangtou is more colloquial, but it is more graphic, and there are actually many controversies and differences in this position, let's take a look together.

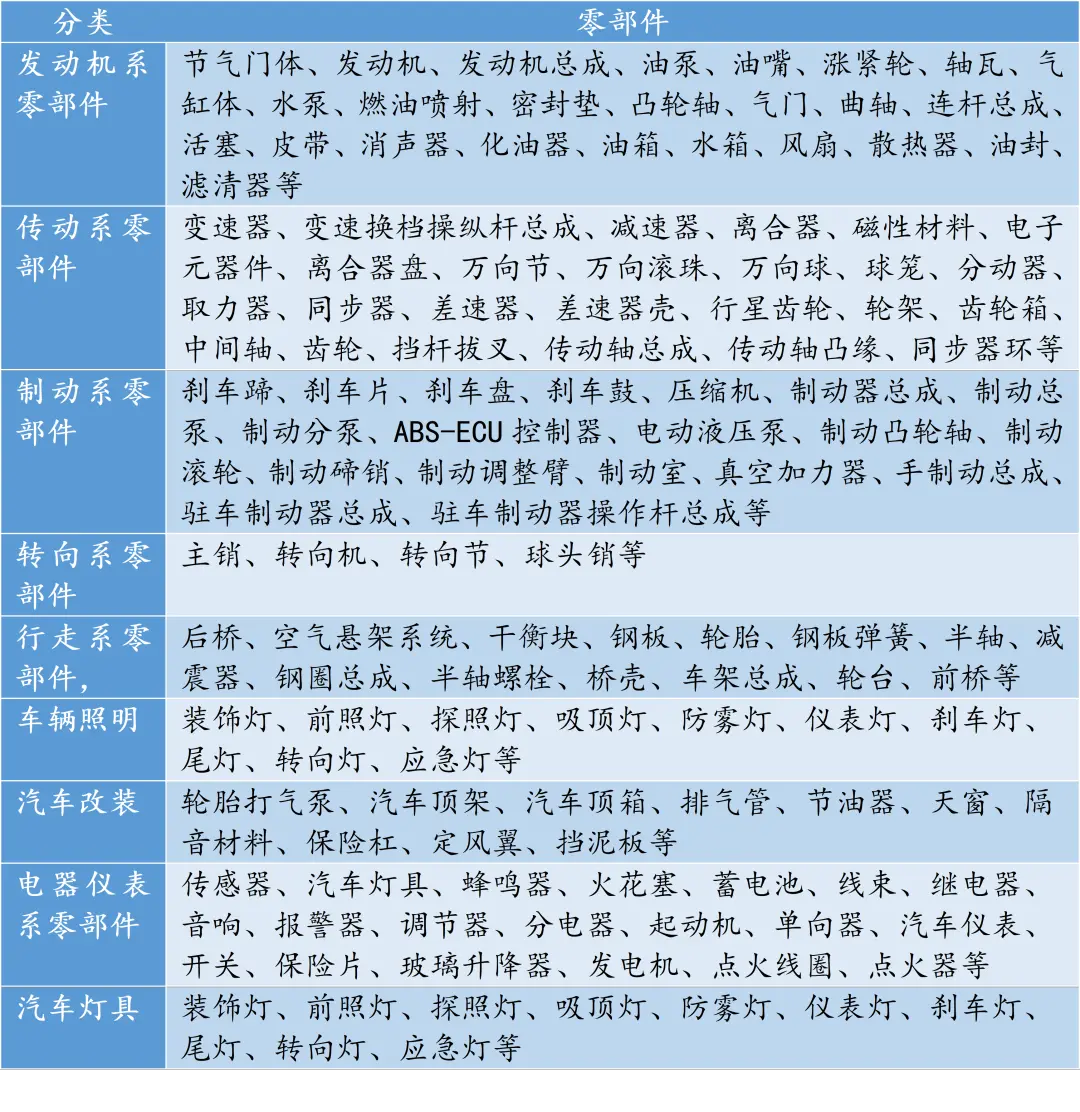

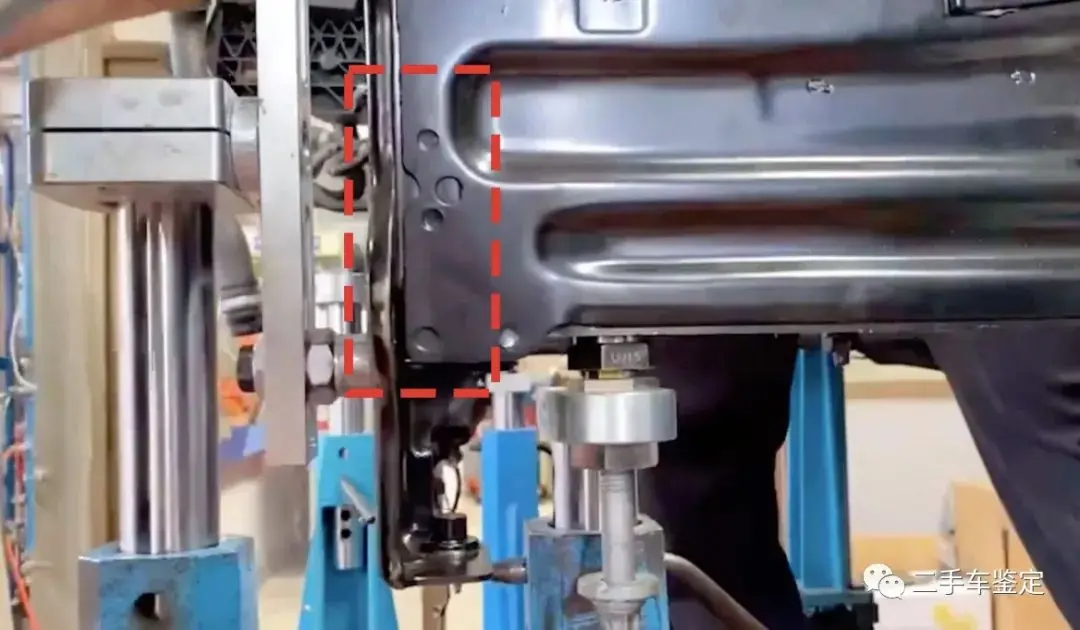

The so-called beam head is actually the position where the front anti-collision beam and the front longitudinal beam are connected, which is generally speaking, the part of the structure at the very front end of the front longitudinal beam (red dotted frame position in the figure above).

The position of the beam head is actually not controversial, the more controversial is the structure of each model in this position, and we judge whether it is an accident car, which is a big contradiction.

Why is there such a big controversy? In fact, because the structure of this location is very complex, many people do not know about it, we will combine the new accident car judgment standards to tell you about this problem.

Many difficulties in second-hand car identification actually lie in the differences in body structure design, different details, and the structural changes and combinations of these different parts will bring different results. Let's first understand what are the common beam head structures?

First, the front anti-collision beam and the longitudinal beam are directly connected (the longitudinal beam has no partition, and the anti-collision beam has no buffer zone)

The most classic structure of this beam head is the beam head of Toyota Camry, the front end of the longitudinal beam has no partition, directly connected with the front anti-collision beam through bolts, and the entire longitudinal beam is a huge buffer zone.

This structure is easiest to identify the accident car, as long as the position of the beam head has any deformation, sheet metal, folds, welding, cutting, twisting and other problems, you can judge the accident car.

Of course, the defect area of this deformation, distortion, welding, wrinkling, and sheet metal must be greater than or equal to 30*30mm to be recognized as an accident car! This is also the new version of the identification standard gives a clear range of damage.

Second, the front anti-collision beam and the longitudinal beam are directly connected (the longitudinal beam has no partition, and the anti-collision beam has a buffer zone).

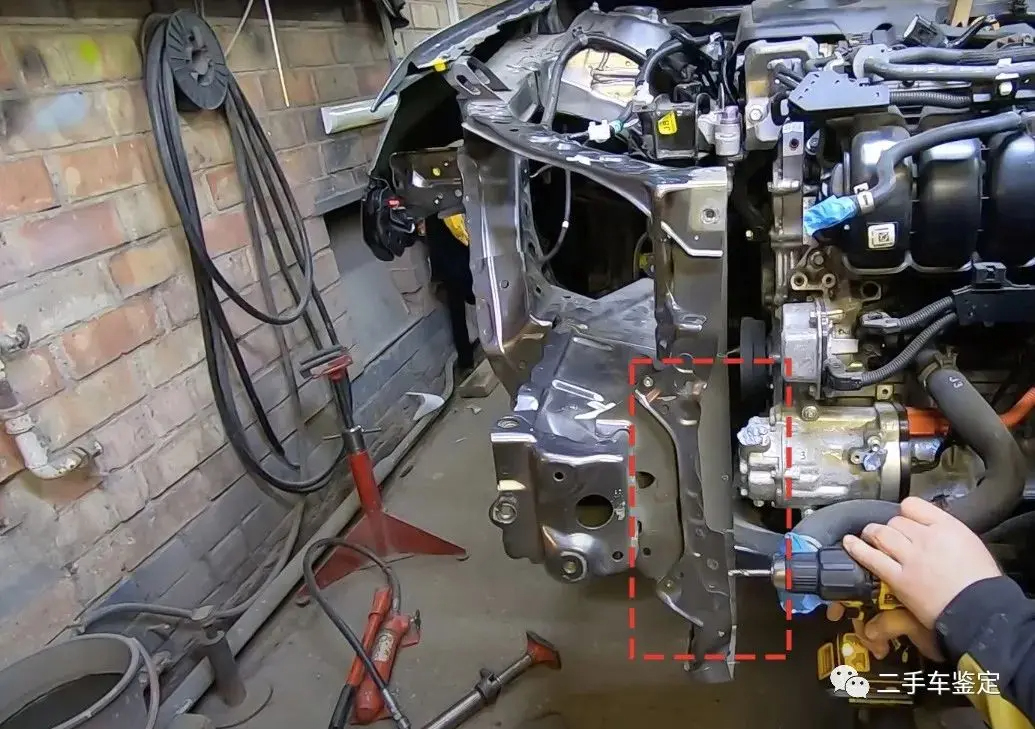

The most classic structure of this beam head is the beam head of BMW and Jaguar, the front end of the stringer has no partition, and the buffer zone directly with the front anti-collision beam is bolted, and the buffer zone is directly inserted into the inside of the stringer.

The identification of this structure is the same as above, the location relationship is clear, and there is no controversy at all.

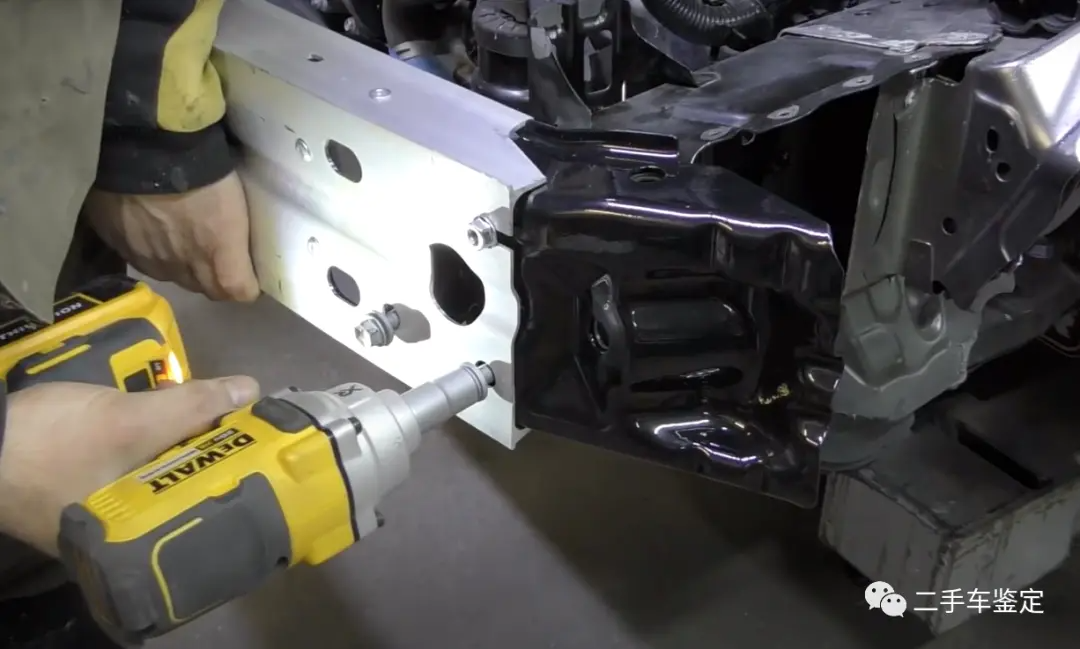

Third, the front anti-collision beam is connected with the longitudinal beam partition

This beam head structure is also relatively common, that is, there is a partition in front of the stringer, and its function is to fix the bolts of the anti-collision beam.

Above, the Mercedes-Benz GLE (Image | Configuration| Inquiry) The special feature of the beam head is that the stringer and the upper fender, lined by a monolithic partition from top to bottom. Although there are not many such structures, special attention should be paid to when identifying, once you are not clear about its structure, it is difficult to judge whether it belongs to an accident car if this position is damaged.

The front of the longitudinal beam has this kind of partition model, you should pay attention to the structure of it and the side stringer when you identify, most of it is connected through the solder joint, the advantage of this is that once there is some collision damage in front of this position, it can be replaced separately!

This design is worthy of affirmation, it is more favorable for later maintenance, and it will not be repaired / cut to repair the entire longitudinal beam because of a little deformation. However, this is also the biggest disagreement when it comes to identifying accident cars. Once this partition is deformed or replaced separately, does it belong to the accident car?

If this separator is deformed or replaced separately, it will not have any impact on vehicle safety. But this partition is part of the front side member, and if judged by the standard, it must belong to the accident car.

This reminds me of the identification of the tank frame in the new version of the standard, which we can use as a reference.

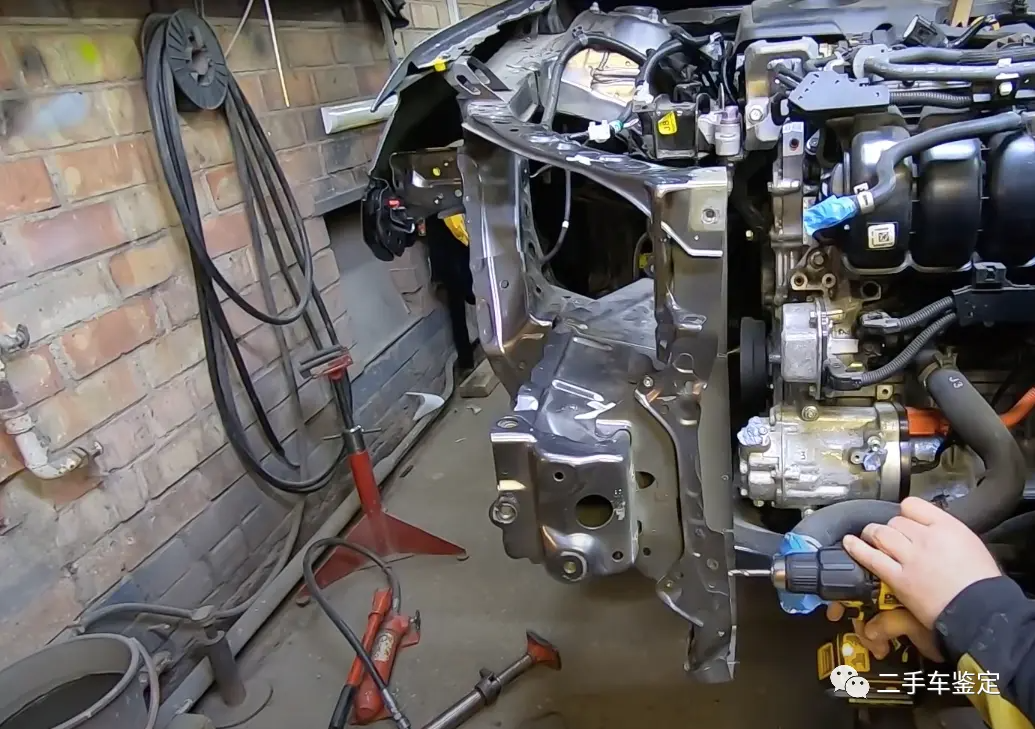

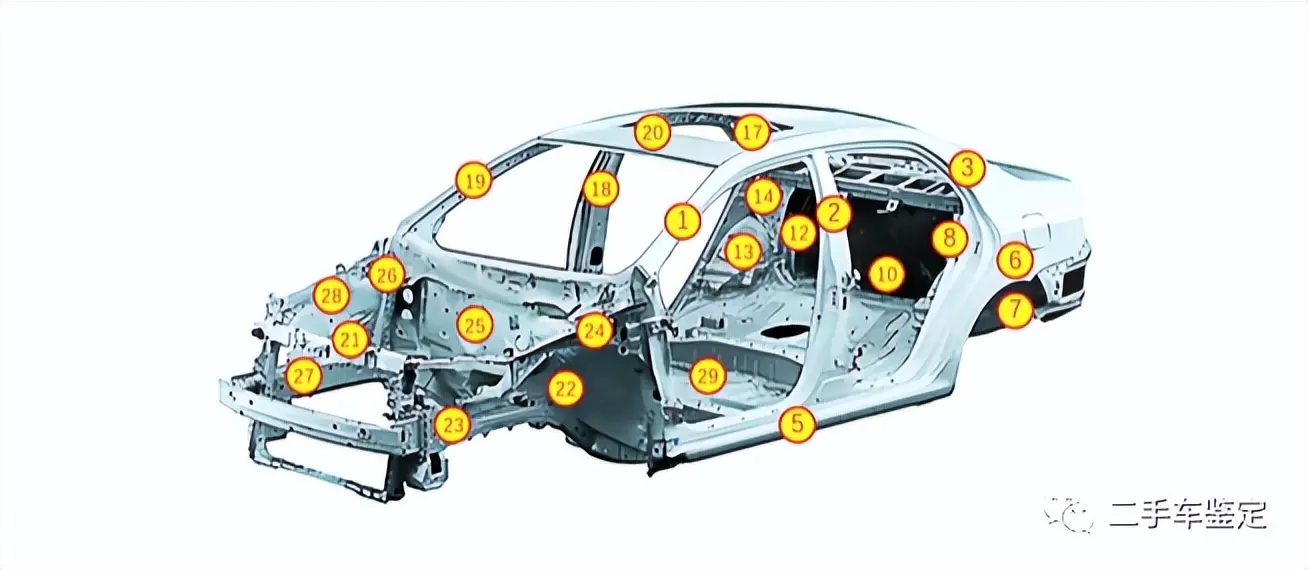

Figure 21 above is the corresponding position of the tank frame. There are two distinctions between water tank frames in the standard: one is a removable water tank frame; One is a non-removable tank frame.

The so-called non-removable tank frame is that the tank frame is welded to connect with its fixing, the most common is the form shown below.

Most of the Japanese tank frames are in this form, and the tank frame is welded to the stringers. Once the frame of such a vehicle tank needs to be replaced or sheet metal, the solder joints need to be separated or re-welded.

In the new standard, once the non-removable tank frame is cut or welded (pay attention to whether the damage range is outside 30*30mm), it can be judged as an accident car.

This situation was also controversial before, but now the new standard gives a clear answer. Even if the tank frame is replaced, it does not have much impact on the safety of the vehicle, but it is still an accident car.

Therefore, when we identify the front side member partition and replace it separately, it will also be identified as an accident car, and there is no need to consider whether it will have any impact on the safety of the vehicle. But some people will feel that such a description will be too serious, and other methods will be needed to solve this problem.

For example, when the customer is buying a car, you have to explain this problem to the customer, and then write a clear description of the accident in the car purchase contract, so that you can avoid risks. The only problem here is that it is necessary to train the sales of the store, so that it clearly knows the definition of the accident car and the actual condition of the vehicle in the store, and many problems after the purchase of the car appear in the sales language, concealing the actual car condition.

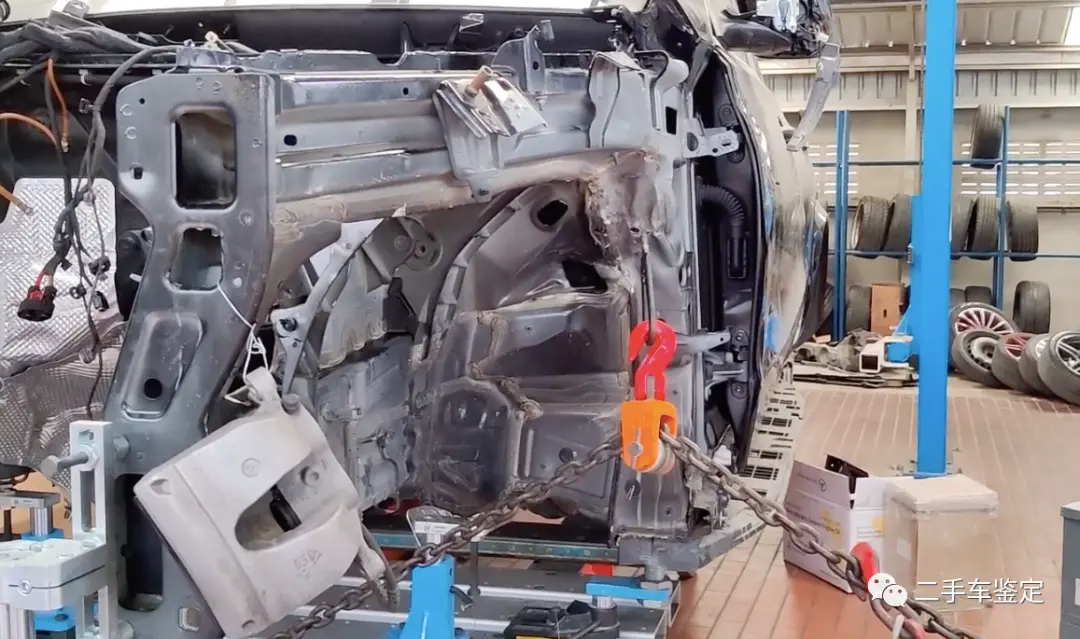

4. The front anti-collision beam is connected with the longitudinal beam partition (there is a connecting area of the anti-collision beam in front of the partition)

This is a design that means a lot, which is the front beam head structure of the Peugeot 3008. The front part of the beam head has a rectangular partition, but there is also a large partition outside the partition, and the two partitions are connected by solder joints.

Although this structure is complex, but the identification of the division of responsibility is very clear, if the outermost large partition is damaged or replaced, then it does not belong to the accident car, but the inner partition and the longitudinal beam is a one-piece structure, if it has sheet metal deformation and other problems, it belongs to the accident car.

The identification and judgment of vehicles often have to be carried out according to the structure of the vehicle, and cannot be judged separately from these structures, so when we identify the vehicle, we must be very clear about the structure of the vehicle, otherwise there will be many questions when identifying.